Multi-channel Flatbed Ultrasonic Squirter System for Inspection of Large Aerospace Composite Panels

Non-destructive testing of aerospace composite parts is most commonly achieved using ultrasonic inspection technologies. While component presenting complex geometries may require dedicated scanning technologies, many aerospace parts are made of composite materials in a panel-like shapes, presenting flat or only slightly curved surfaces. Through-Transmission Ultrasonic testing represents the method of choice to perform non-destructive inspection of such parts.

Through-Transmission Ultrasonic testing represents the method of choice to perform non-destructive inspection of large aerospace panels made of composite materials.

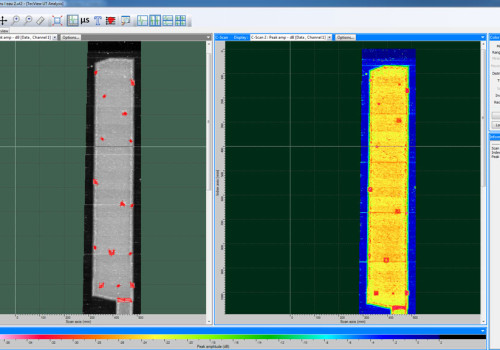

Through-transmission inspection can quickly reveal the presence of discontinuities inside an inspected part. This is done by monitoring the transmitted signal for amplitude losses. Large flat or semi-flat panels can be inspected in a simple raster scan pattern by synchronizing the movement of both the emitting and receiving probe. High resolution C-Scan images can be generated from the ultrasonic waves transmitted through the inspected composite panels.

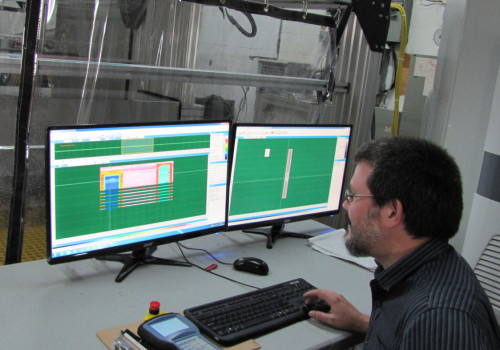

While the scanning rate of such inspections can be very high, inspection time can suffer from panels with large dimensions. The scanning indexes performed at the end of each scan line, can have a non-negligible impact on the overall scanning time. An efficient way to maximize the scanning rate is to minimize the amount of indexes using multi-channel scanning technology with multiple ultrasonic probes. Instead of moving a single pair of probes across the surface of the parts, arrays of probes are used in pairs to scan across the inspected panel, the elements of the emitting array being fired simultaneously or one after the other. This not only saves the time that would have been lost during scan indexing, but could potentially cut the inspection time by a factor corresponding to the number of elements of the probes array.

One of the limitations of using multiple probes, which must be overcome, is the probes response uniformity within the array of probes. Array normalization tools are required to obtain a uniform response from all the probes and generate C-Scans that are equivalent to what would be obtained in a conventional single channel system.