Composite Fan Blade Inspection

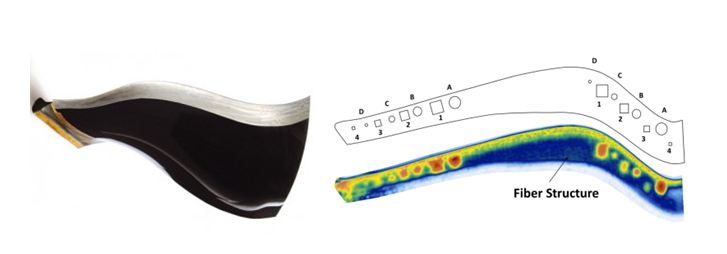

Turbofans currently designed for the next generation of medium-haul airliners are constructed from composite materials with titanium shaped leading edges. Because of safety and reliability requirements, these composites blades must be inspected for any manufacturing anomalies/defects.

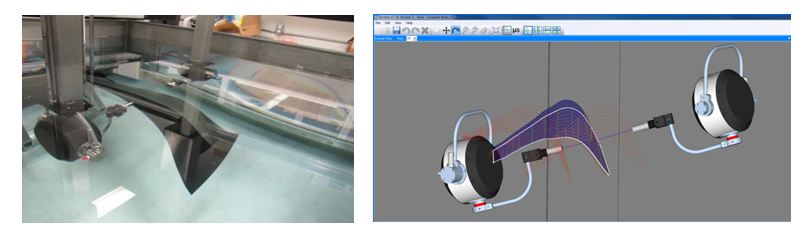

Typical composite engine fan blade with titanium leading edge

Scan3D™ from TecScan, a non-destructive testing solution designed to inspect these composite fan blades using interactive software tools, 3D motion control and a part entry module. This innovative 3D Ultrasonic Testing (UT) solution allows the user to perform advanced blade inspection for disbonds and/or fiber damage using 3D contour following with arbitrary scanning motions on the curved sections of the blade.

The revolutionary Scan3D™ solution includes a high-precision immersion ultrasonic scanner with full 3D surface following capabilities for accurate inspection and full capture of the blade. It consisted of a 10-axis immersion tank with two independently controlled X and Y carriages, two Z axes, and two fully automated and submersible Gimbal/Gimbal manipulators. The system is fully controlled via a centralized system control station that included 3D data acquisition, data reporting and data analysis modules.

The two submersible Gimbal/Gimbal manipulators are fully automated and could achieve high-speed rotational motions with precise and low backlash probe manipulator. They are designed to minimize gravitational forces applied on the scanner Z axis, allowing accurate 3D scanning.

The challenge of inspecting the bonding in the blade and more precisely between the composite layer and its titanium leading edge protection can be overcome with the use of TecScan’s Scan3D™ Ultrasonic Scanning System. When combining the importation of a blade’s CAD files with ultrasonic teach/learn positions and internal sound path calculations, both pulse-echo and through-transmission testing could be performed based on the calculated parametric space which defines the ultrasonic transducer motion.

Blade and Gimbal/Gimbal manipulators are controlled and animated live in 3D

Example of result from the inspection of the titanium-composite bonding with a through transmission setup