Exploring the Potential of Automated Eddy Current Testing with TecView® EC

While manual eddy current inspections are common, crucial aerospace parts that necessitate high-sensitivity inspections are better suited for automated testing. Aero-engine turbine disc surfaces, spool welds, borehole, and firtree inspections already benefit from automated eddy current scanning systems.

Eddy Current: A Vital NDT Technique for Detecting Surface Flaws in Aerospace Components

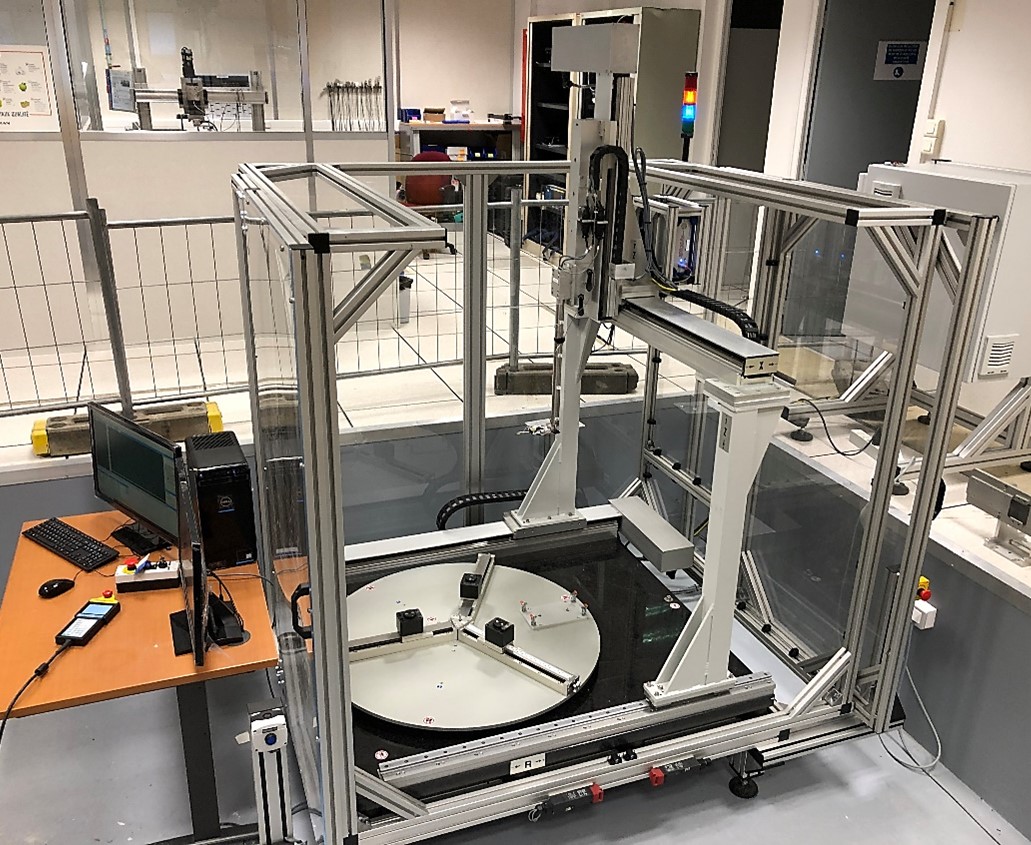

Many of the aforementioned components exhibit uncomplicated geometries featuring either axial or circumferential symmetry. Nonetheless, parts with more intricate surfaces would derive advantages from the precision and consistency of Automated Eddy Current Inspection Systems.

New Automated Eddy Current 3D Inspection Capabilities

TecView® EC 3D provides the necessary tools for Automated Eddy Current Systems to perform comprehensive 3D inspection of complex parts. Starting from a CAD model of the surface to be controlled, precise scanning trajectories can be established to ensure thorough coverage of the inspected part.

TecView® NDT Software – 3D EC

Using specially designed probe holders and adapted probes, combined with proper management of probe-to-part pressure, adaptability of the probe holder to small variations of surface curvature, and proper signal processing, repeatable and reliable high-resolution eddy current scanning can be achieved on different surfaces. This is demonstrated in the 3D projection of an eddy current amplitude C-Scan acquired on an aero-engine outlet guide vane (OGV) blade surface.

Automated 3D Mapping of a High frequency eddy current C-Scan of an OGV blade

Related Content

Automated Eddy Current Testing Systems

Advanced NDT Software : TecView® EC