Advanced Eddy Current Scanning Solution for Aero Engine High Pressure Compressor Rotor Spools

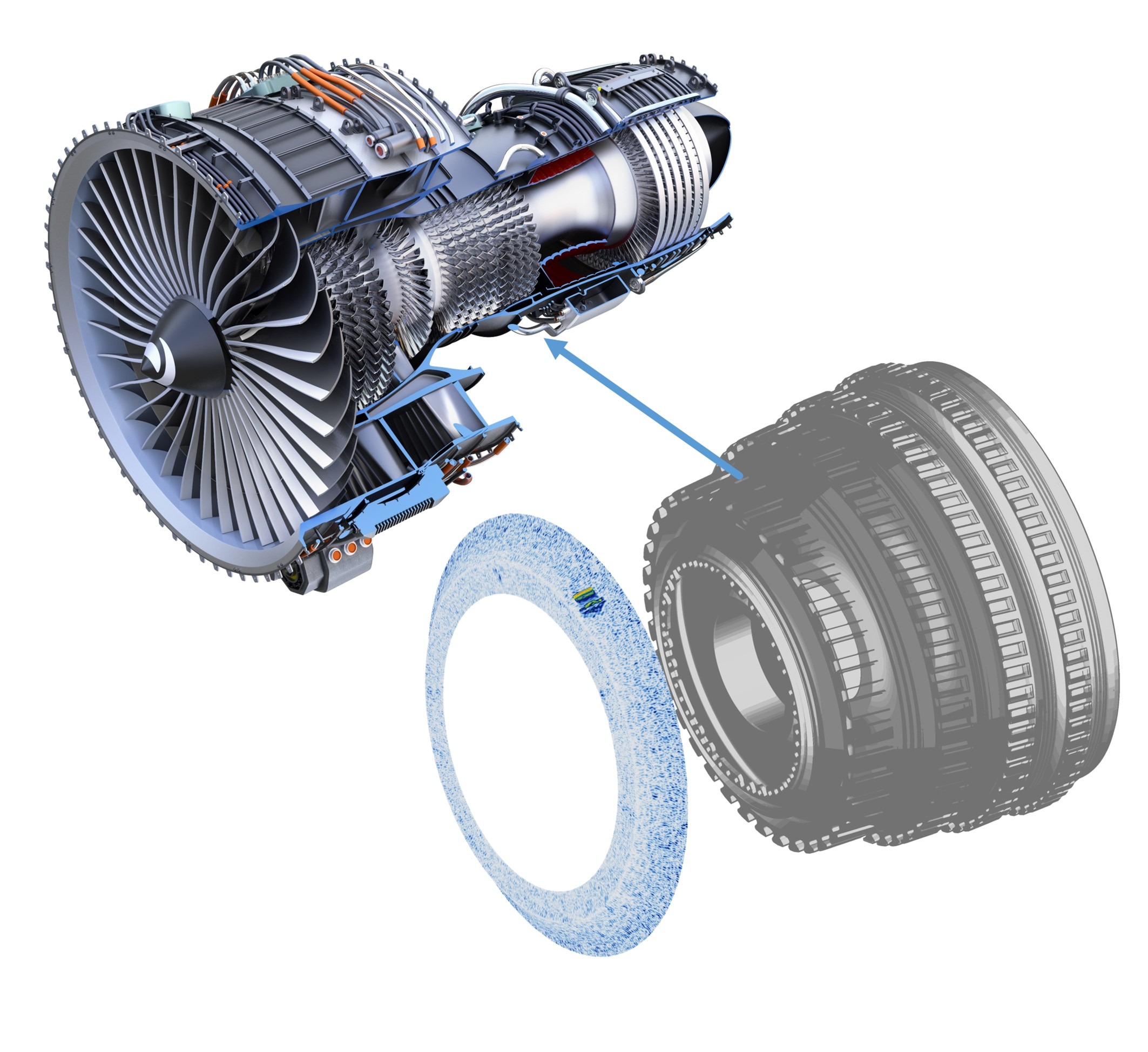

Aircraft engine MRO (Maintenance, Repair, and Overhaul) plays a crucial role in maintaining engine continuous operation and flight safety. The high-pressure compressor rotors (HPCR) section of the engine is among the components that require periodic inspections to detect the tiniest manufacturing flaws as well as any crack produced by the loads, fatigue or temperature variations encountered in flights. The HPCR spool section consists of multiple spool stages, where the hub-to-web transitions and the web areas are required to be inspected for any surface defects or cracks that could occur during operation or at the manufacturing stage. The inspection challenge in such situations consists of automating the inspection process, which require reaching inside the HPCR spool through either ends of the rotator spool to inspect the targeted web and hubs-to-webs transition areas, which are closed spaces with little room to fit a probe manipulator, as well as being nonvisible to the operator.

The inspection challenge in such situations consists of automating the inspection process.

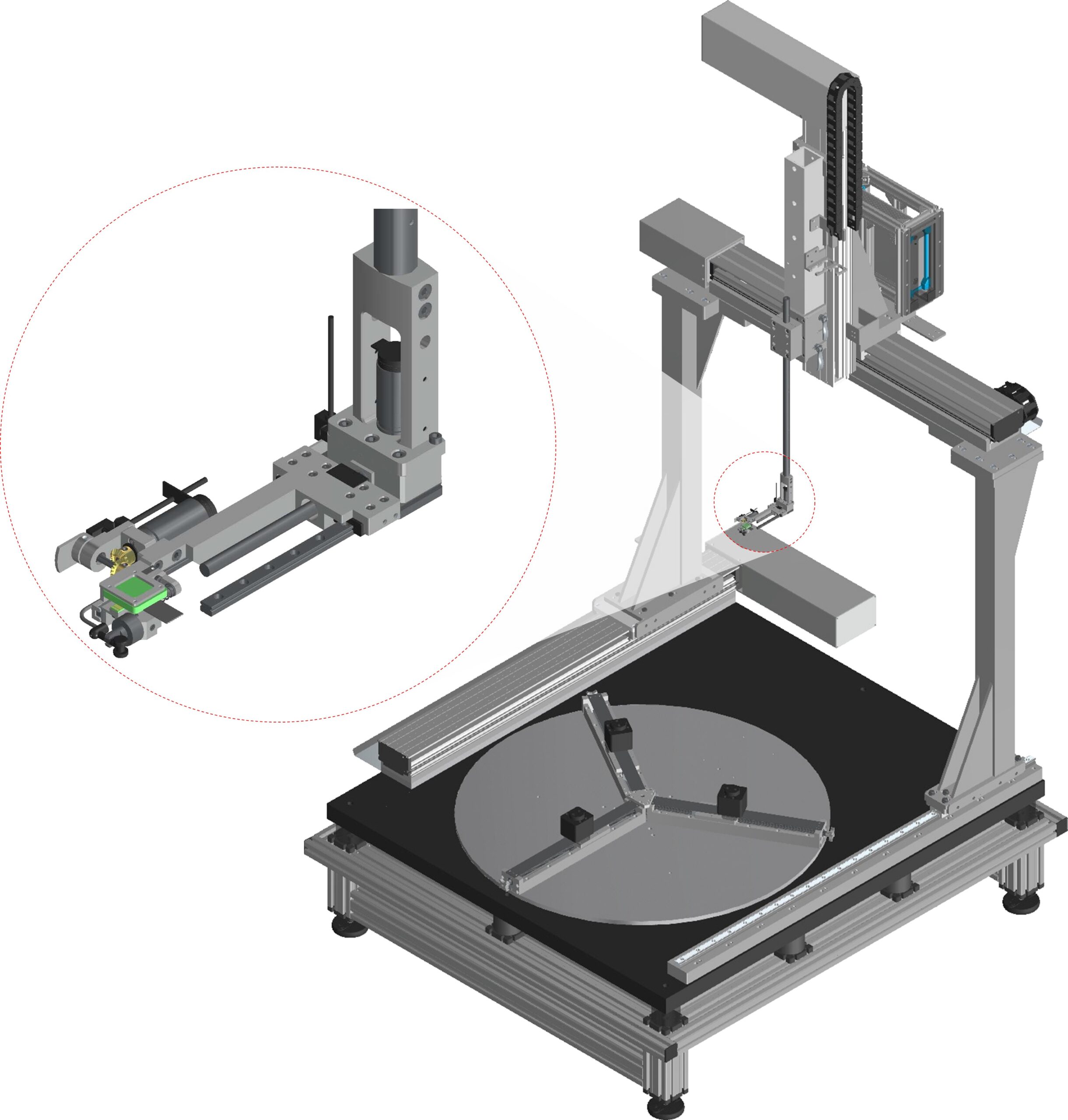

To meet these requirements and overcome the complex geometrical obstacles of the HPCR spool, an advanced eddy current scanning solution and 3D modeling tools were developed and tested using high pressure compressor spool samples with simulated crack like defects. This also included the development and implementation of the eddy current inspection technique for some pre-selected stages in the compressor rotator spool.

This article was originally published in Quality Magazine

For more details see: Quality Mag – NDT | Eddy Current