Composite Skin Structure Inspection

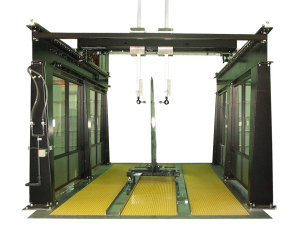

Ultrasonic Gantry Squirter System

Carbon/epoxy skin and aluminum honeycomb composites are used extensively in aviation and aerospace applications. Their application is attractive because of the reduced weight which enables better fuel economy and lowers operating costs. Reliable nondestructive testing solutions and systems are required to perform proper inspection of such composites which in turn would ensure the structure safety and quality and prevent any failure. Ultrasonic through-transmission testing is the technique most commonly used to inspect sandwiched honeycomb composite materials, mainly for the presence of bond failure or crushed cores. This testing technique produces A-Scan, C-Scan and B-Scan images of the inspected structure which help to examine their integrity and characterize defects such as disbonds and delaminations.

TecScan’s Ultrasonic Gantry Systems recently used for the inspection of aircraft rudders (one of the main flight control surfaces of the Canadian F/A-18 aircraft). The Rudders with composite honeycomb sandwich panels were inspected with the Ultrasonic Gantry System using water jets (Squirters) for the detection of disbond between the honeycomb cores and the composite skin panels. Results from the Gantry showed that Water Ingress within the rudder’s structure have degraded the epoxy adhesives that bond the carbon epoxy skins to the aluminum honeycomb core.

Rudders attached to the vertical stabilizer of F/A-18 aircraft

For more complex aerospace composite structures, fuselage sections, wing panels and radome structures, Ultrasonic Gantry System combined with our Scan3D™ technology represents the most advanced and revolutionary solution to investigate these structures and perform complex 3D contour following C-scans. This solution is also can be custom designed to meet clients’ needs.