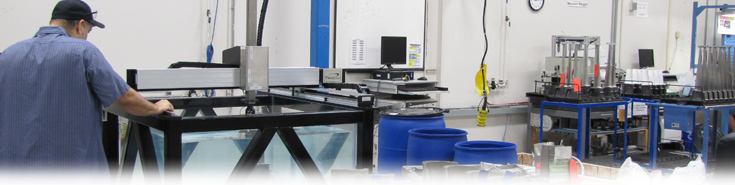

Standard Immersion Systems

TecScan manufactures Standard Immersion Systems (TS series) for non-destructive ultrasonic testing applications. This standard series of ultrasonic scanning systems is designed to be versatile and rugged. The configurations of the TS systems range from simple 2 automated X-Y axis manual Z-axis, to 5 fully automated X,Y,Z,G,G (Gimbal/Gimbal) axes. The 5-axis configuration is suitable for ultrasonic testing of curved surfaces with TecView™ contour following option.

Controlled by our TecView™ UT data acquisition and analysis software package, the TS series are designed with standard immersion tank sizes packaged to suit clients’ needs and requirements for laboratory and industrial applications.

A multitude of options could also be used along with a selected TS model: Automated or Manual Gimbal/Gimbal or Swivel /Gimbal assemblies, Turn Tables and Bar Stock Indexer.

TS systems with standard immersion tank sizes !

Immersion scanning systems for laboratory, aerospace & industrial applications.

TecScan Standard Immersion Systems

TS 0500, 1000, 2000, 3000 Series

The TS series of ultrasonic scanning systems come in with pre-selected tank sizes which are designed for easy operation and low maintenance. A multitude of options could be used along with a selected TS model:

| Model | Description | Scan Distance | Options | |

|---|---|---|---|---|

| TS-0500 | Manual Lab Scanner – Manual X & Y axis – Manual Z Axis (search tube xxmm) – Aluminum Structure – 1/2″ Acrylic Tank |

36″x24″x18″ | – Motorized Z-Axis – Manual Gimbal Gimbals – 18″ through tank turn table |

|

| TS-1000 | Automated Lab Scanner – Motorized X & Y Axis – Manual Z Axis (search tube xxmm) – Aluminum Structure – 1/2″ Acrylic Tank |

36″x24″x18″ | – Motorized Z-Axis – Manual Gimbal Gimbals – 18″ through tank turn table |

|

| TS-2000 | Industrial Scanner – Motorized XYZ Axis – Steel Structure – 1/2″ Acrylic Tank |

48″x36″x24″ | – Stainless Steel Tank – Motorized Gimbal Gimbal – 24″ through tank turn table (cap. 200 lbs) – TecView™ Contour Following module |

|

| TS-3000 | Large Industrial Scanner – Motorized XYZ Axis – Steel Structure – Stainless Steel Tank |

60″x36″x36″ | – Through Transmission Yoke – Motorized Gimbal Gimbal – 24″ through tank turn table (cap. 200 lbs) – TecView™ Contour Following module |

*These specifications may vary according to clients requirements.

Non-destructive testing applications

TecScan’s Standard Immersion Systems are non-destructive scanning systems designed for ultrasonic testing of MRO (Maintenance, Repair, and Overhaul) of aircraft components, aerospace structures, power generation and industrial applications. They come in standard immersion tank sizes and are tailored for laboratory, aerospace & industrial applications. The systems consist of a mechanical scanner and an industrial workstation housing all required electronics. For fully automated standard immersion systems, the scanning process is completely controlled by our TecView™ UT software package, which is designed to handle the whole NDT process, from motion control all the way to data analysis, interpretation & reporting.

LABORATORIES

Quality control inspectors/laboratories use TecScan’s immersion systems as tools and means to inspect aircraft or any industrial related components in order to validate it fit for service (free of defects). These immersion scanners are perfectly suited for laboratory testing, inspection procedure development and non-destructive testing training facilities.

- TS-1000

- TS-500

AEROSPACE

Aircraft inspection involves the inspection of components and structures; our standard immersion systems are trailered to inspect aerospace components for detection of cracks, disbonds in composites, fatigue damage and corrosion. Some of these TS systems are currently used to inspect complex aircraft geometries such as turbine blades, wing panels and some engine components.

INDUSTRIAL

Manufacturing industries for steel, aluminum and titanium use TecScan’s Standard Immersion Systems to detect weld defects, porosities and stress cracks to determine their product and service capabilities.

Main Features

- High speed UT scanning

- High motion resolution and accuracy

- Motion control up to 12 axes

- Windows based, multi-tasking software TecView™ UT

- Full waveform digitalization

- Real-time A, B and C-Scans

- High quality encoders and DC servo motors

- Linear amplifiers that minimize the noise interfering with UT signals

- Hardware for Pulse on Position scanning

- Home switches for high position repeatability